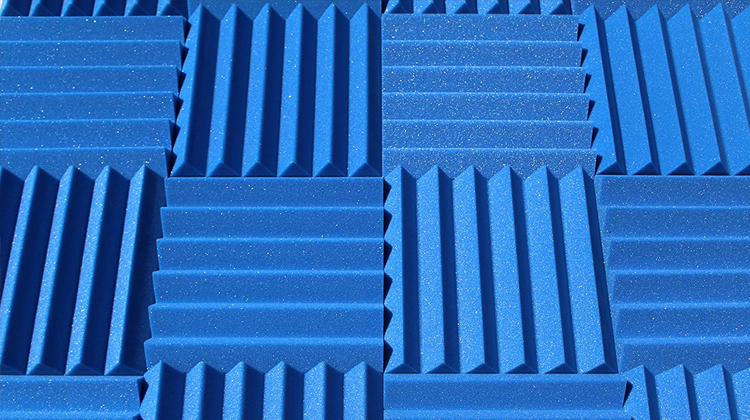

Across various industries, fiberglass is the material of choice due to its superior strength, durability and corrosion resistance. However, cutting fiberglass requires precision and the use of specialized tools to ensure clean and accurate results. Choosing the right industrial fiberglass cutting tool is critical to achieving efficient, high-quality cuts while maintaining safety and minimizing waste.

Manufacturers have several reasons to use fiberglass as the primary material in their product designs. Its versatility, strength and insulating properties, as well as its ability to resist corrosion from water and chemicals, make it a low-maintenance, long-lasting composite material of choice. These qualities make glass fiber composites the material of choice for many industries, including marine and alternative energy applications.

To fully utilize the potential of fiberglass, manufacturers must select the proper fiberglass cutting tool for their application.

While designing with fiberglass offers unique advantages, cutting and handling the material can present challenges. The strength of fiberglass and the demands of marine and wind manufacturing environments means that the cutting tool you choose must be durable and reliable. A suitable fiberglass cutting tool must be able to cut dry, wet, coated or impregnated braided and multiaxial reinforcements as well as chopped strand mats. Fiberglass comes in a variety of orientations (unidirectional, bidirectional, multiaxial, or random), and each construction method can affect the speed, throughput, and blade type required for your cutting system.

AOL recommends using a round blade for cutting fiberglass for most applications. The blades are designed to easily crush and destroy materials containing fiberglass. Increased cutting pressure increases blade life. Circular blades cut fiberglass with less splintering than reciprocating blades.

Fiberglass can also be cut with a 10-sided blade designed for cutting advanced textiles such as stitched fiberglass. This blade offers maximum versatility and adaptability when added to a heavy-duty tool head.

Various parameters of glass fiber cutting machine:

|

Technical parameters / model |

AOL-1625 |

AOL-1825 |

|

Effective working area |

1600x2500mm |

1800x2500mm |

|

Multi-function tool |

Oscillating knife, round knife, pneumatic knife, drag knife, half cutting knife, press wheel, V-CUT Knife Tool, milling cutter, drawing marker pen, ink cartridge inkjet, cursor positioning, camera positioning edge patrol |

|

| safety devices |

Four corners emergency stop, anti-collision safety device using infrared induction, safe and reliable |

|

| Cutting tool configuration | Oscillating knife or drag knife or round knife | |

|

Cutting speed |

200-1200mm/s |

|

|

Cutting thickness |

1mm-3mm Other thicknesses can be customized according to the material |

|

|

Applicable materials |

It can be used to cut Silicone Rubber Fiber Cloth similar to the material, and different configurations can be selected for different materials |

|

|

Material fixing method |

Vacuum partition adsorption |

|

|

Transmission port |

Network port |

|

|

Transmission system |

The X\Y axis is divided into two kinds of rack or belt |

|

|

rated power |

11kw |

|

|

Rated voltage |

380V±10%/220V±10% Optional |

|

|

Control System |

Chinese and English LCD touch screen |

|

|

Operating environment |

Operating environment Temperature 0-40°C Humidity 20%-80%RH |

|

|

Support file format |

AI、PLT、DXF、PDF、 PCE、XML |

|

| Overall size |

3600x2400x1200mm |

3600x2600x1200mm |

| Other configuration | ||

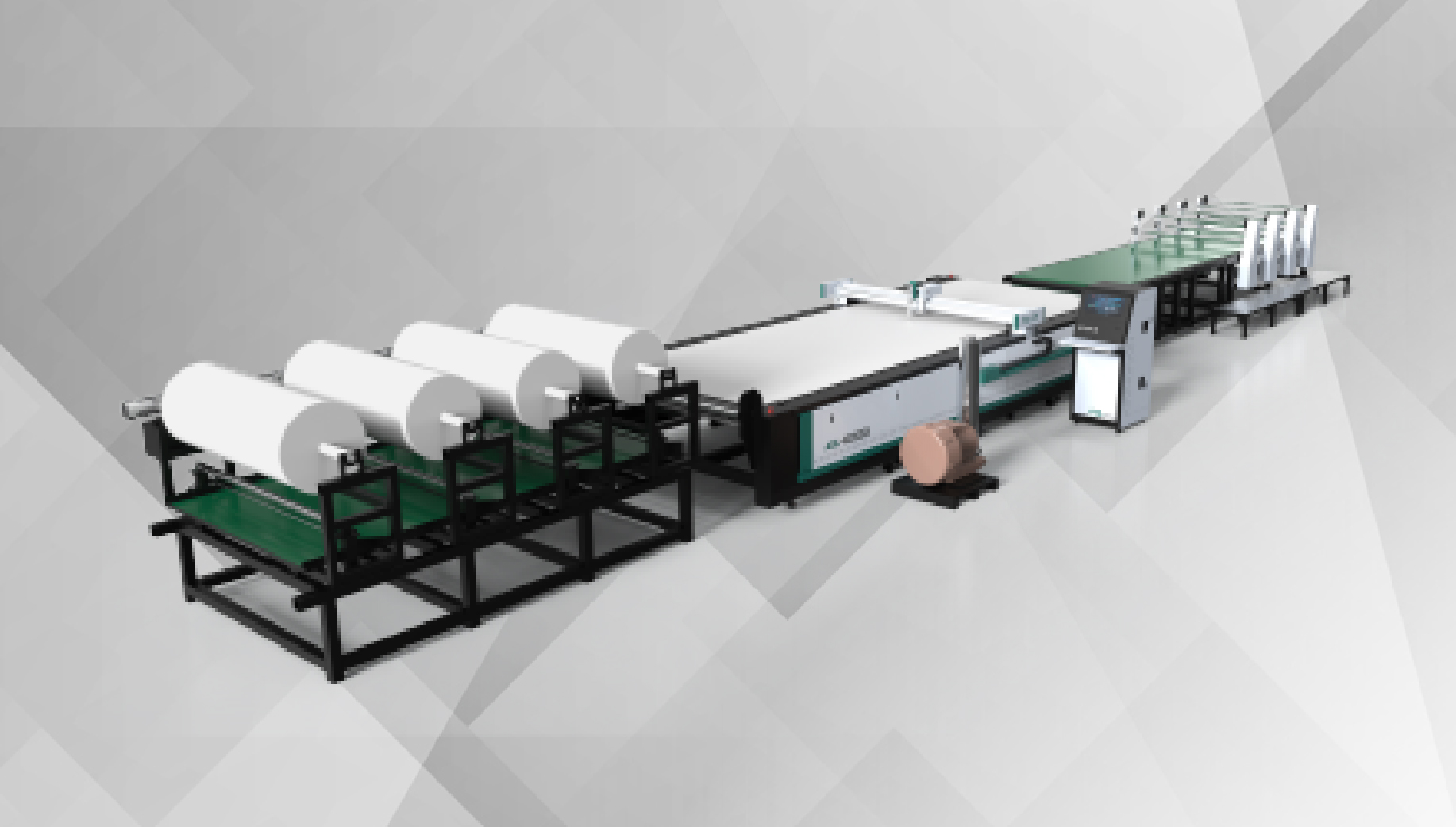

In many cases, glass fiber cutting will exceed the length of the equipment itself. We have an automatic feeding system that allows manufacturers to introduce coiled glass fiber to the work surface more accurately and controllably, thereby simplifying the production process.

Selecting the proper industrial fiberglass cutting tool is a critical step in ensuring an efficient, accurate and safe fiberglass cutting operation. Factors such as fiberglass type and thickness, safety features, accuracy requirements, durability, and ease of use need to be considered so you can make informed decisions that lead to successful cutting results. Remember to always put safety first and follow best practices in working with fiberglass materials for the best results.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/