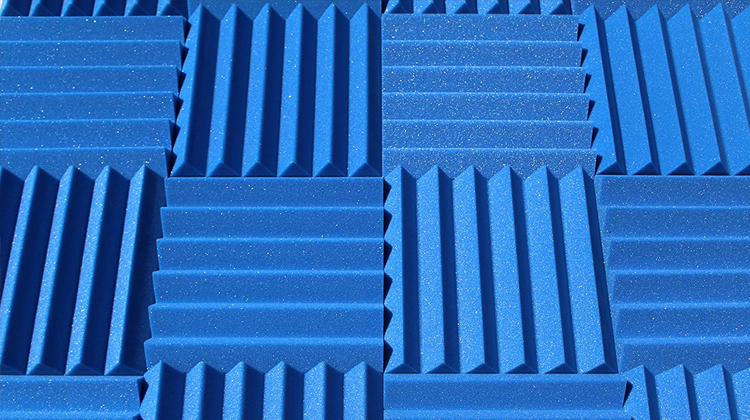

The sealing industry is the production of parts that prevent fluid or solid particles from leaking from adjacent joint surfaces and prevent external impurities (such as dust and moisture) from invading the interior of machinery and equipment, or have the ability to prevent fluid or solid particles from leaking from adjacent joint surfaces and prevent The same category of economic activity that measures the intrusion of external impurities (such as dust and moisture) into the interior of machinery and equipment is called the sealing industry.

Although the seal is small, its role makes it a basic component and accessory in the main industries of the national economy such as national defense, chemical industry, petroleum, coal, transportation and machinery manufacturing, and occupies a very important position in the development of the national economy. In recent years, with the rapid economic growth, the seal manufacturing industry has maintained double-digit growth. Due to the particularity of this industry, special attention is required when cutting. Recently, many friends have asked me what to pay attention to when choosing a gasket cutting machine, and what are the advantages compared with other cutting equipment. To the question listed some points for your reference!

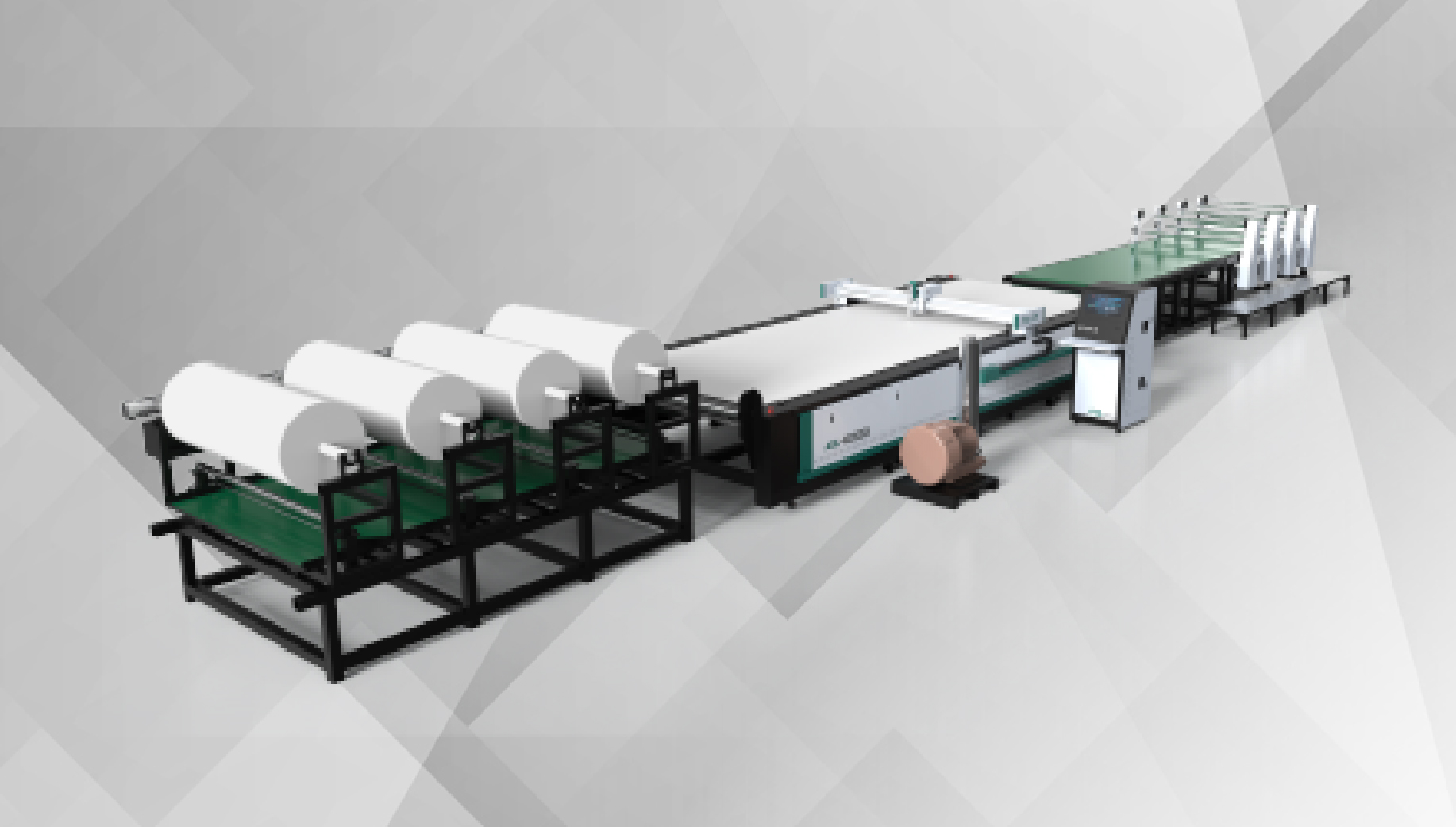

The gasket cutting machine can cut a variety of non-metal flexible materials. Common composite material industries include glass fiber, carbon fiber, boron fiber, aramid fiber, synthetic resin, rubber and other materials.

The overall competitiveness of my country's sealing industry is not strong. As we all know, in our country, the sealing industry can be said to be the smallest industry, but the products can be used in conjunction with large industries. Whether aviation, navigation, petroleum, chemical industry, or machinery, power generation, metallurgy, mining, etc., are inseparable from seals. In short, wherever organics, pumps, pipes, and valves are, rely on seals. Therefore, although the industry is small, the scope involved is very wide.

But there are still many industry pain points in cutting, such as the following:

1. There are more and more special-shaped non-standard orders, and traditional processes cannot be processed

2. The punching machine has a taper, and the technical requirements cannot be met

3. The hardness of the special material is high, and the punch cannot be processed manually

4. The processing utilization rate of punching machine is low and the scrap rate is high

5. The risk factor of punch processing is large, and there are many types of molds

6. Professional workers are difficult to recruit and manage

7. There are burrs in the edge cutting, and the secondary grinding takes time and money

8. Product accuracy requirements are getting higher and higher, and traditional processes cannot be realized.

At present, there are two cutting methods in the market:

1. Manual cutting: non-standard, low precision, serious material waste, special-shaped can not be cut, high cost

2. Stamping equipment for stamping: chaotic die management, high customization cost, and low material utilization

3. Vibrating knife cutting machine cutting, blade cutting, high precision, neat cutting edge without burrs, saving a lot of manpower and material resources

Sealing gasket cutting machine equipment industry advantages:

①AOLCUT self-developed software is imported with one key, and ordinary workers are skilled in 2 hours

②Super Nesting Master software, material utilization rate increased by more than 20%

③The transmission system adopts German rack and pinion transmission, with an accuracy of ±0.1mm

④ Select Japanese Panasonic servo system, the production efficiency is increased by more than three times

⑤Select special material tool, vertical cutting without taper and edge without burr

⑥Save more than 800,000 labor and raw materials every year, and greatly improve product competitiveness

⑦Optional image laser projection technology, automatic cutting of leftovers at will

⑧ Unique multi-partition technology, the adsorption force is increased by more than 5 times

⑨Anti-static system of the whole machine to maximize the protection of personnel safety

⑩Industry exclusive database optional

Industry equipment configuration selection recommendation:

Recommended Models: AOL-1625DC Fixed Rack Single Blade (Pneumatic Knife); AOL-2125DC Fixed Rack Single Blade (Pneumatic Knife)

Optional accessories:

Projection positioning system:

1. Visually confirm the pattern cutting position

2. Drag the layout at will after typesetting

3. Automatic nesting software

4. Sealing industry database

Imported milling cutter spindle: for hard non-metallic plates with a thickness of 5--10mm

Industry software introduction:

①Nesting software: There are many types of graphics and different sizes. The software automatically nests, without manual nesting and typesetting, saving time and efficiency

②Sealing industry database: When cutting international standard gaskets, there is no need for professional CAD drawing personnel, just enter the data of the layout to form

③ Outstanding advantages in the industry: market share, software advantages, hardware advantages, industry transaction data, equipment customization solutions, creating maximum benefits

The above is the relevant introduction to the content of the sealing gasket cutting machine. If you still have questions about the equipment or want to know more, please contact us, and we will have professional personnel to answer all your questions as soon as possible!